Silane Crosslinked Cable Compounding

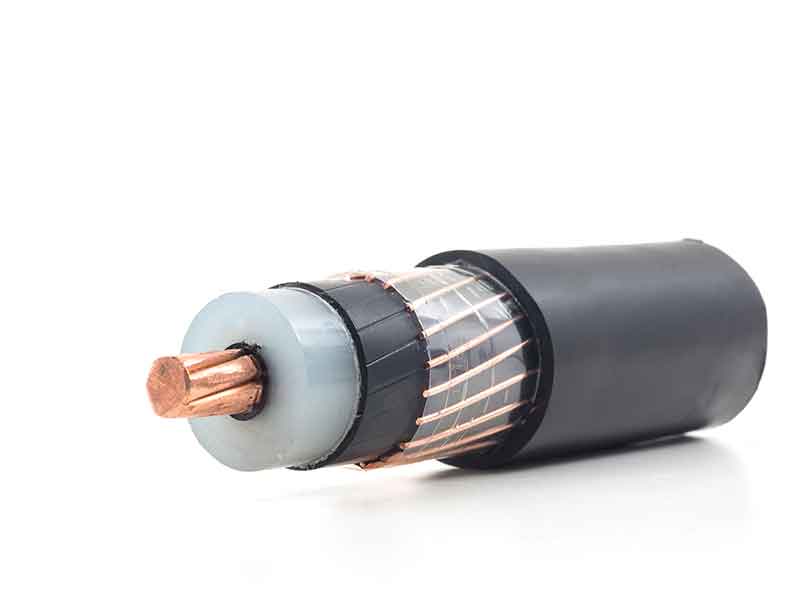

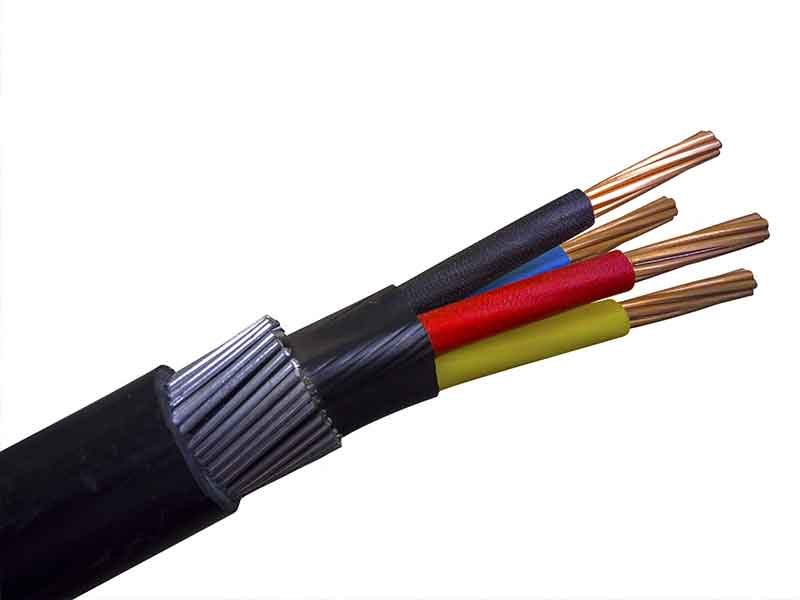

Polyethylenes (PE) have outstandingly good insulation properties. A temporary temperature rise, e.g. due to peak loading, can however cause a complete breakdown of PE cable insulation. The relatively low softening or melting point leads to thermo-mechanical failure or even dripping of the Insulation. Cross-linked polyethylene (PEX) is more thermosetting than thermoplastic. It can therefore be used at significantly higher operating temperatures, is mechanically stronger, more resistant to organic liquids, and often enables thinner wall thicknesses. Various cross-linking methods are used. Silane cross-linkable cable compounds are also known as PEX-b or Sioplas®.

Sioplas® was developed in 1968 by Midland Silicones (now Dow). In the first stage of this two-stage process, vinyl silane is grafted onto the polymer chain with peroxide activation. In the second stage, pipe is conventionally extruded from the grafted compound with a catalyst masterbatch. Cross-linking takes place offline in an aqueous or steam environment. Ever since this process was developed, Buss Kneaders have been used in the first stage and for producing the catalyst masterbatch.

For cable insulation up to 10 kV, silane cross-linkable PE compounds have been globally proven as the most cost-effective materials and are produced in large quantities.

Compounding requirements for silane crosslinked cable compounding

The grafting process requires precise control of the temperature profile and retention time. A liquid silane-peroxide mixture is fed into the polymer melt by a membrane or piston pump and intensively mixed distributively. The silane molecules are linked to the polymer chains by radical grafting according to precisely defined residence time and temperatures.

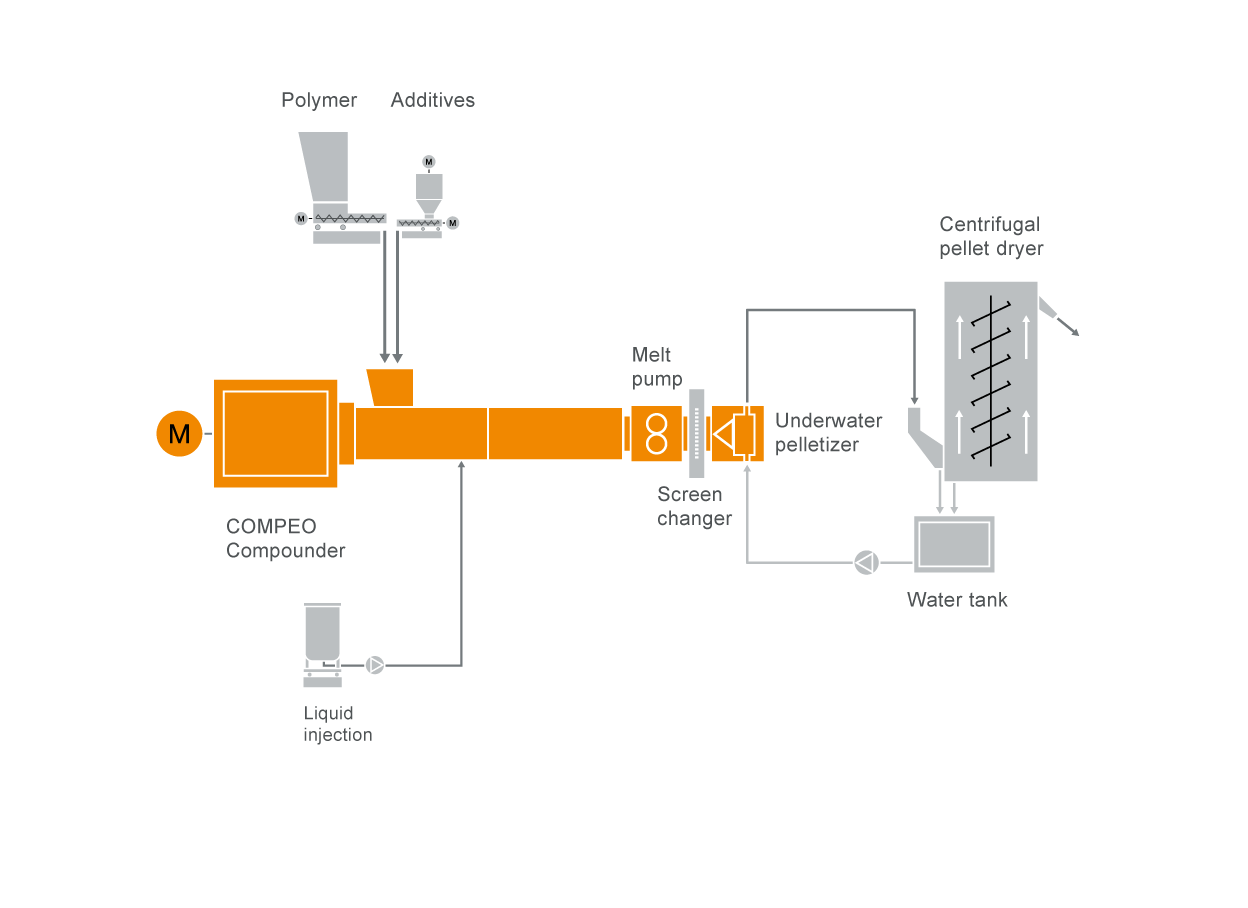

For this reactive extrusion process, the BUSS Kneader’s within the silane crosslinked compounding system’s characteristics are of key importance. The silane-peroxide mixture can be directly injected into the melt pool at the process-optimized position. Distributive mixing immediately afterwards enables a uniformly high graft yield, and minimal scorching effects compared with other systems. The the silane crosslinking compounding process can be monitored at any time by temperature readings at several locations in the compounding system’s processing section. This enables online quality assurance and control. A pressure-regulated melt pump is utilized to feed the underwater pelletizer. Each processing stage can therefore be optimized independently. The hinged housing of the BUSS Kneader gives fast and easy access to ensure high system availability. High throughputs are easily attainable. All these skills together are the plus of the silane crosslinked cable compounding technology by BUSS.

The modular design of the entire BUSS Kneader line makes it easily adaptable to all requirements. Together with the widely based BUSS processing expertise, the BUSS Kneader has always been a good choice for compounding silane crosslinked cable insulation with high possible quality and investment security.

Typical plant layout for silane crosslinked cable compounding

BUSS silane cable compounding systems offer the following specific benefits

Learn More

Downloads

-

COMPEO