COMPEO

The new compounder generation. Incredibly flexible.

The polymer industry’s innovation and earnings potential lies in the production of extremely high quality compounds. End products should be reinforced, scratch-resistant, flame-retardant, weather-resistant and at the same time resource-saving. This requires a compounder which easily and thoroughly mixes in significant amounts of additives. Meet COMPEO, the new state-of-the-art compounder delivering more diversity in its application, greater flexibility in process engineering, and increased value added in compound manufacturing.

COMPEO – in motion!

„Incredibly flexible.“ This is the promise of our new COMPEO compounder generation for the polymer and plastics industry. COMPEO is the new, ultra-modern compounder with twin screw extruder from BUSS, which offers more variety in application, more flexibility in process engineering and a higher added value in compound production.

Incredibly different

The new compounder generation

New configurable process zone

Compounding technology for polymers

Innovative discharge concept

Innovative control concept

Swiss Quality at its best

COMPEO – the best from all series!

The allrounder among the compounding systems

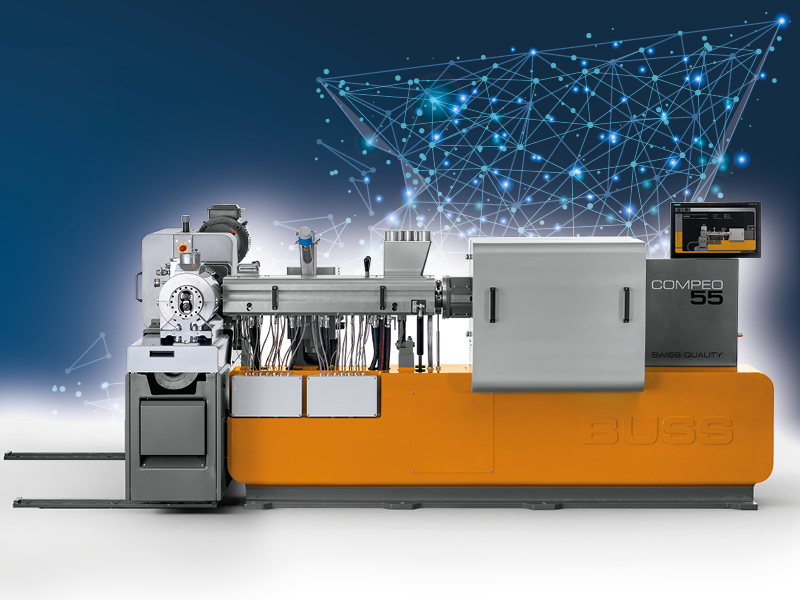

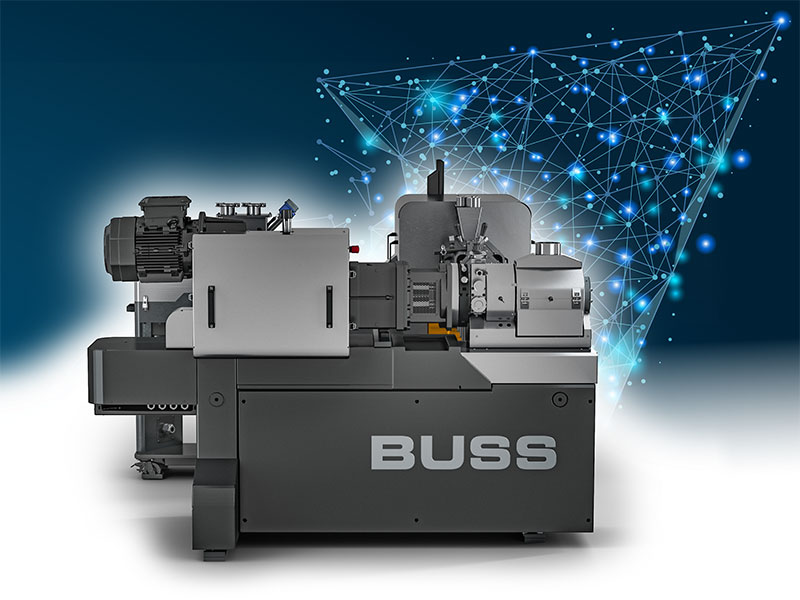

COMPEO combines its predecessors’ performance and robustness in a unique, multifunctional series. The series was developed for all temperature ranges up to 400°C (specific model only). It has a process window that is unparalleled. Given the system’s modular construction and novel process geometries, COMPEO can be used within an extremely diverse application spectrum, extending far beyond previous Buss Kneader applications – from temperature-sensitive thermosets to demanding, technical thermoplastics.

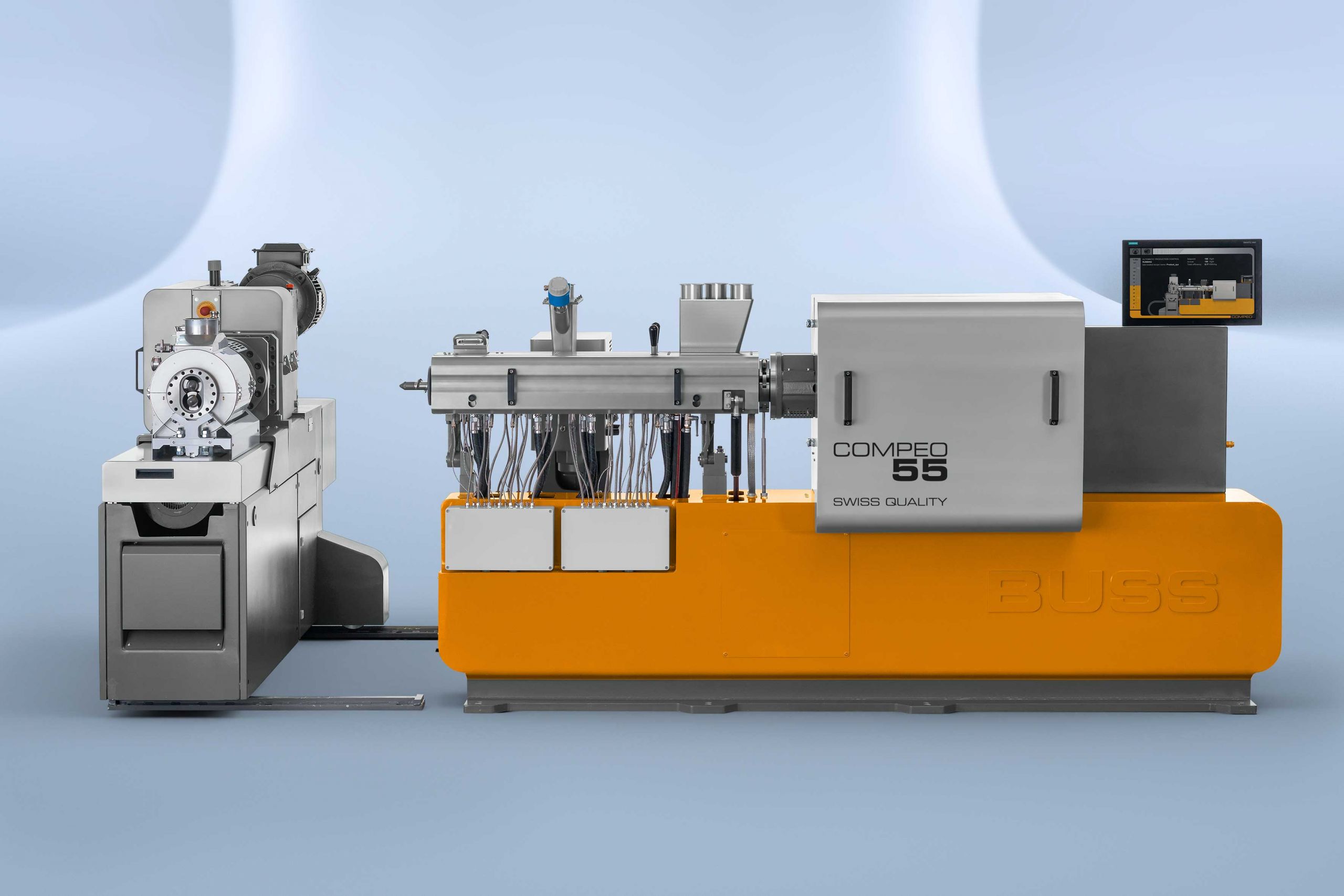

The newly developed machine concept

Thanks to its modular structure, the COMPEO series can be precisely configured to meet the specific compounding application. Systematic standardization of the modules used results in considerable investment cost savings. Maintenance outlay is kept low by using highly resistant surface-hardened materials in the process zone. The ergonomics of the COMPEO system design simplifies operation and simultaneously reduces application errors and downtimes.

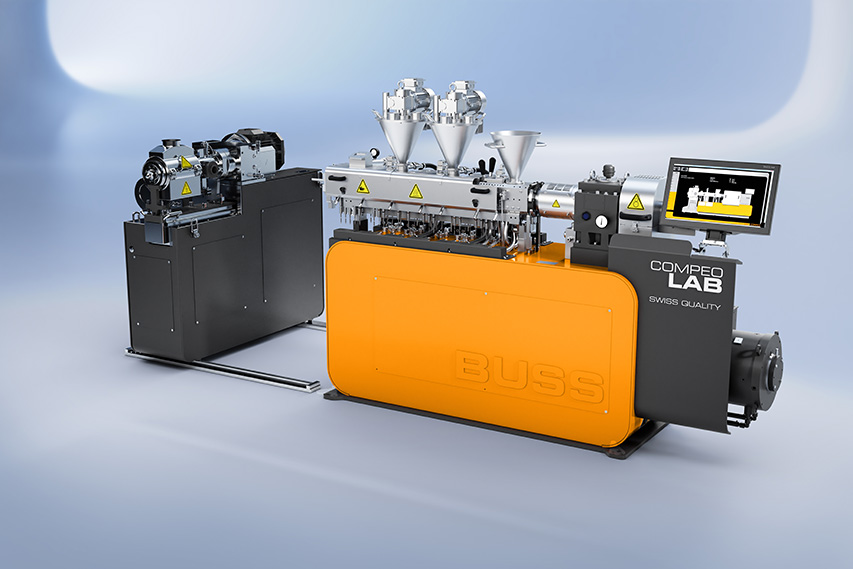

Improved raw materials feed

The new COMPEO series achieves the performance of its predecessor series using lower speeds, but also due to ideal fill levels. As a standard, raw materials are metered in freefall via an enlarged inlet opening. Alternatively, inlet screws or side feeders can be used. Thanks to the operating principle of the twin screw and backventing, they ensure efficient feeding, even if there are high filler contents.

Very operator-friendly and energy-efficient

When designing COMPEO, emphasis was placed on ergonomics, ease of maintenance, and energy efficiency. Pipes and lines are laid mostly inside the machine behind easy-to-clean panels. The gearbox is covered with a soundproofing hood that also improves operational safety. To minimize energy losses, the process section is thermally insulated.

One design – different sizes!

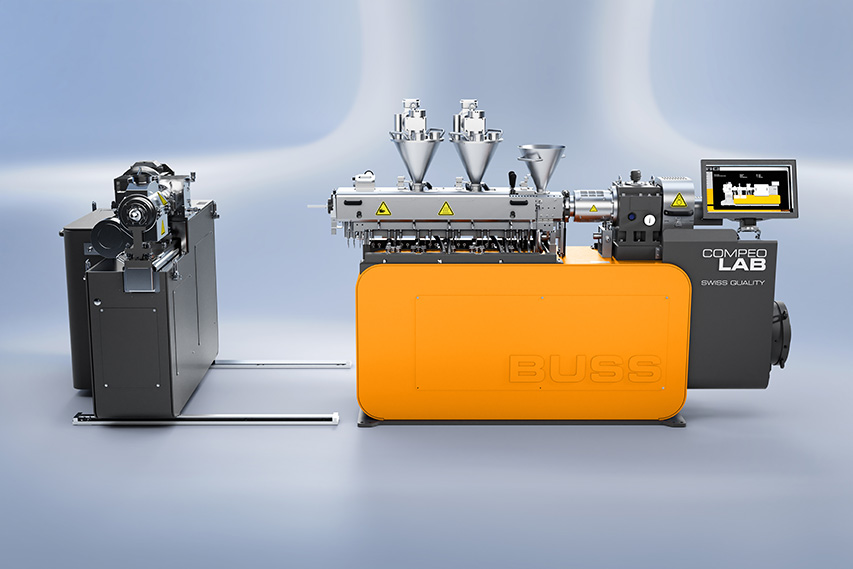

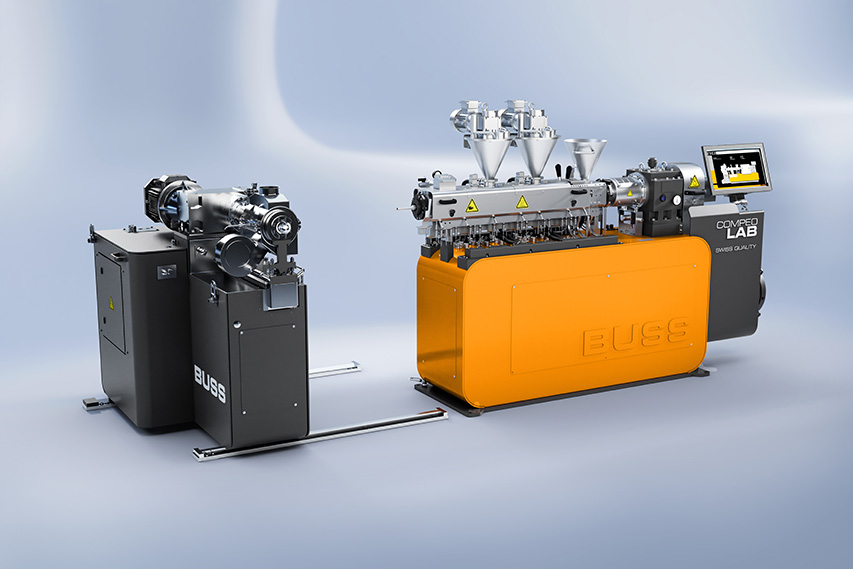

COMPEO LAB

COMPEO 55

COMPEO 88

COMPEO 110

COMPEO 137

COMPEO 176

COMPEO – new geometries for greater flexibility!

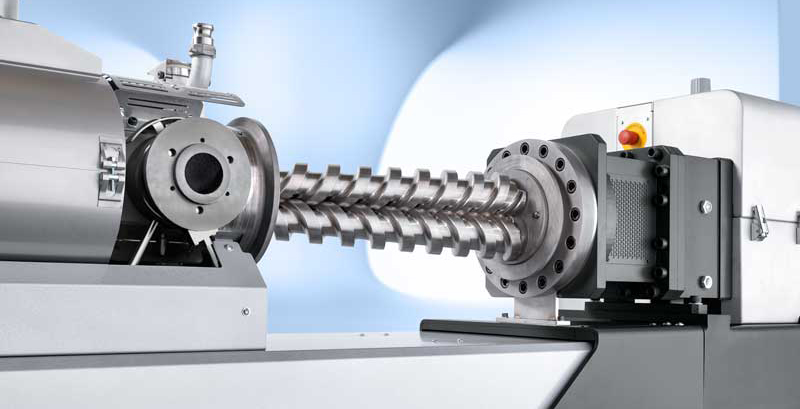

COMPEO’s innovative operating principle

In the basic version with two inlet zones, polymers, additives and some of the fillers are fed through the first intake opening. The polymers are molten and mixed with the additives in the melting zone. In the second feed zone, further fillers are added via a side feeder and distributed homogeneously in the downstream mixing zone. Incredibly flexible. Incredibly different. Volatiles and entrapped air are removed in the degassing zone before transfer to the discharge unit. The processing length, type and number of feeding units, temperature, degassing and process geometries are defined according to the compounding application.

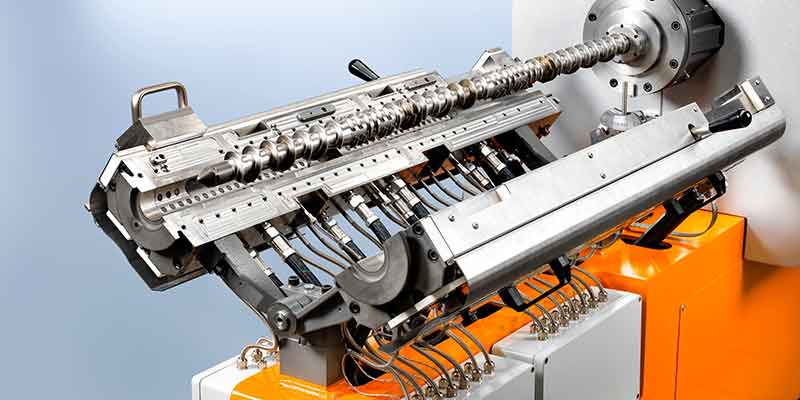

New screw geometries extend the process window

The new COMPEO series screw geometries ensure high throughputwith up to 20% lower RPM compared to previous models. At the same time, increasing the volume-related torque by 15% enables the configuration of longer mixing zones. That results in more stable process conditions without a higher energy input. The systematic free-form surface design of the screw flights ensures evenly intense shearing of the product and eliminates local overheating.

The configurable process zone of the COMPEO compounder opens up completely new process engineering possibilities through the application of mixing and kneading elements with two to six rows of flights. The combination of traditional three and four flight elements with newly developed mixing elements allow, for one thing, achieving goals which in the past conflicted with each other, such as high specific throughput with controllable energy input. For another, the COMPEO process window is considerably larger than those of previous models. Throughput can be varied in a ratio of 1:6, increasing both system flexibility and user-friendliness. The high throughput ratio is particularly advantageous for starting up, for small lots, and for in-line processes, where the downstream unit requires consistent product quality even with greatly varying throughput rates.

COMPEO – efficient down to the last detail!

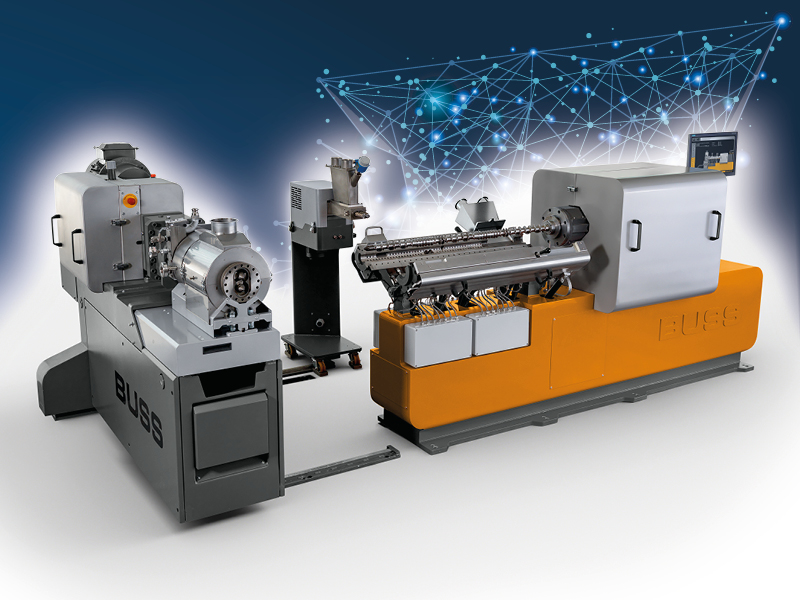

Innovative discharge concept

Pressure build-up at the end of the production process is at least just as important for perfect pellet quality as fully homogeneous mixing of the various raw materials in the compounding step. The discharge unit is decisive for this. It ensures optimum und reliable pressure build-up required for downstream units such as screen changers and pelletizers, independent of the compounder. The innovative COMPEO also enables the realization of hybrid systems for processing widely differing products.

Efficiency, quality and user-friendliness

The new COMPEO discharge unit, based on the principle of a conical twin screw, is designed to run in a metered method. As a result, the entire pressure build-up takes place in the slowly rotating twin screw, thus reducing temperature increases at the transition from compounder to discharge unit. The operating principle of the screw pump also guarantees maximum conveying efficiency in case of higher back pressure, enabling minimization of the speed and potential temperature increase. The COMPEO discharge unit has a wide range of application possibilities and is exceedingly user-friendly. The retractable housing gives full access to the conveying screws for cleaning and maintenance.

COMPEO – system control 4.0

Intuitive operation of control panel, Industry 4.0 connectivity

The touch-screen equipped control system is based on a state of-the-art controller (Siemens or Allen Bradley) and has an OPC-UA interface for connection to higherlevel IT architectures. This interface makes the system fully Industry 4.0 compliant. The modular software is structured according to the system configuration and can be operated intuitively.

The control system works with stored formulation parameter sets, which makes it possible to switch between formulations with the push of a button. All essential system parameters such as fill levels, flow rates or quantities, pressures, temperatures, and outputs are visualized, recorded, and archived. Defined process parameters such as temperatures, power consumption or specific energy input, and thus the efficiency of the system, are continuously monitored by the control system. Optionally, the system can also be maintained via remote diagnosis and remote maintenance.

Unique features

With its unique functions, COMPEO offers new, convincing advantages and benefits for a highly varied scope of application:

- Extremely wide range of applications

- Novel screw geometries

- Considerably extended process window

- High output at lower speeds

- High robustness and operational safety

- Improved energy efficiency

- Innovative discharge concept

Future-proof system

BUSS has developed the new COMPEO compounder generation to meet current and future plastics industry requirements. With a wide range of applications, a large operating window, high flexibility and robustness, as well as improved process stability, but also operational and operator safety, energy efficiency and reduced operating costs, COMPEO can be applied for a wide array of applications.

Strong service concept

The BUSS service team is available to you worldwide for professional support in taking care of your new COMPEO compounding system. From project engineering, process-related advice, installation, and commissioning to training and unparalleled service, we are your partner to protect your investment for the long term. This also includes retooling or revamping the system later, moving the system or modernizing the compounding line.

Learn more

-

COMPEO

-

Kunststoffe International: Compounding Systems with Variable Kneading Flights