Compounding Systems for Polycarbonate Compounds

Polycarbonate (PC) based compounds belong to the technical plastics sector, often known as Engineering Plastics due to their main strengths and respective applications: technical components with excellent impact strength over a wide range of continuous operating temperatures whose excellent transparency enables widespread optical and data medium applications. PC based compounds are also a preferred construction material due to their good flame retardant properties.

Typical applications

Polycarbonate was first mentioned at the end of the nineteenth century, but not produced on a large scale until the 1950s, by Bayer (now Covestro) and General Electric (now Sabic), followed later by other manufacturers. Apart from the aforementioned advantages, great significance is now attached to the following properties as well: excellent electrical insulation, sterilisability and combinability with other plastics such as ABS, ASA and PBT into customized blends accordingly.Polycarbonate (PC) based compounds have therefore become very important for electronics and electrical applications as well as in medical technology, the automotive and aircraft industries.

Compounding requirements

The compounding system is critically important for all Polycarbonate (PC) based materials. PC ingredients, mostly in powder or chip form, are compounded together with additive components into pellets such as for transparent moulding compounds in the compounding system. In many cases reinforcement agents, flame retardants, dyes or the aforementioned blend partners are also added. Compounding these materials is therefore very demanding and requires customized solutions such as some of the following. Polymer components must be melted as gently as possible, flame retardants have to be perfectly distributed, and reinforcement fibers must be added and processed in such a way as to optimize mechanical properties.

All these requirements are well mastered by sophisticated compounding process technology accordingly. The BUSS Kneader can make much better use of its strengths here than other compounding systems. Thanks to extremely uniform and moderate shear rates, yellowing is minimized because no hotspots occur. This is critically important for transparent formulations. Moreover the BUSS Kneader’s characteristically perfect handling of wide viscosity ranges enables very wide and dependable operating windows. PC blends, reinforced, flame retardant or high-viscosity formulations and other combinations can usually be compounded without any change in screw geometry.

The BUSS Kneader’s two-stage system clearly separates the compounding and pressure build-up stages so that each stage can be independently optimized. Pressure build-up for pelletizing PC compounds is usually by gear pump.

The hinged housing of the BUSS Kneader ensures fast and easy access for high system availability. Together with broadly based BUSS process expertise, the modular design and therefore adaptable arrangement of the entire compounding line make the BUSS compounding systems and the the BUSS Kneader first choice for complex polycarbonate production, which has provided maximum investment security for decades.

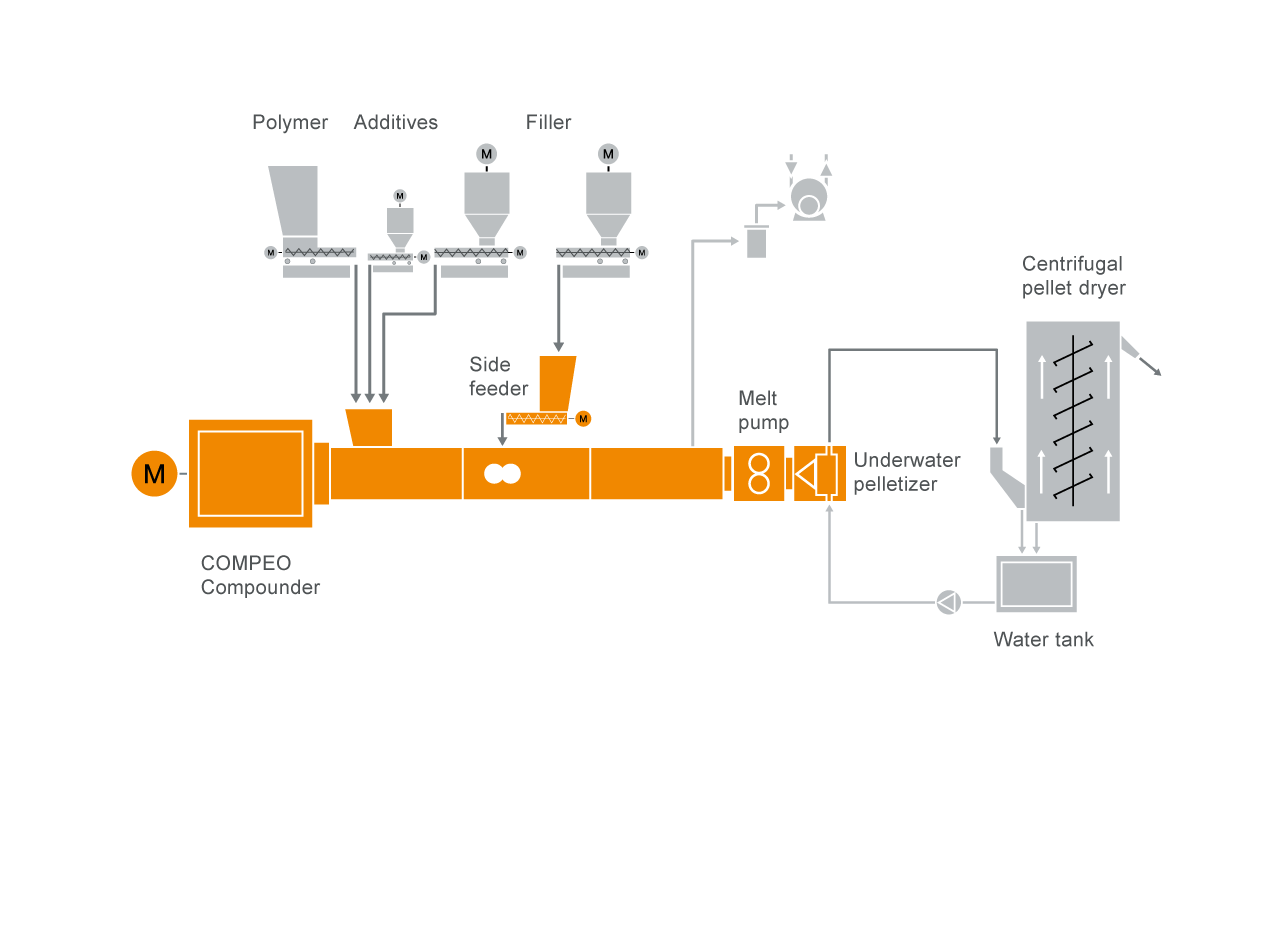

Typical compounding plant layout for Polycarbonate (PC)

BUSS compounding systems offer the following specific benefits

Learn More

Downloads

-

COMPEO

-

Laboratory Kneader MX 30