Compounding machinery for Thermoplastic Elastomers

Thermoplastic elastomers constitute a family of materials combining the characteristics of elastomers with the recyclability and processability advantages of plastics. TPEs do not have to be vulcanized like rubber, and can be processed by conventional methods such as injection moulding, extrusion and blow moulding.

Similar to thermoplastics, TPEs become plastic when heated and elastic when cooled down again. In elastomers, this behaviour is due to chemical cross-linking. In TPEs, it is the result of physical cross-linking and any changes in behaviour caused by heating are reversible.

When the material is cooled down, new cross-links are established, which bond the elastic blocks into rigid three-dimensional networks. This means that TPEs show elastic properties that are similar to those of elastomers, while allowing for repeat deformation and recovery as known from thermoplastics. Thermoplastic elastomers are thus free flowing and formable. TPEs have a block structure (A-B-A), typically with thermoplastic end blocks (A) and an elastic midblock (B), placing TPEs midway between thermoplastics and elastomers. ISO/EN/DIN 18064 furthermore classifies the wide variety of TPEs in 7 classes: TPA, TPC, TPO, TPS, TPU, TPV and TPZ. The 3rd letter designates the respective subclass: A for Amide, C for Copolyester, O for Olefin, S for Styrene, U for Urethane, V for Vulcanisate, and Z for various other materials.

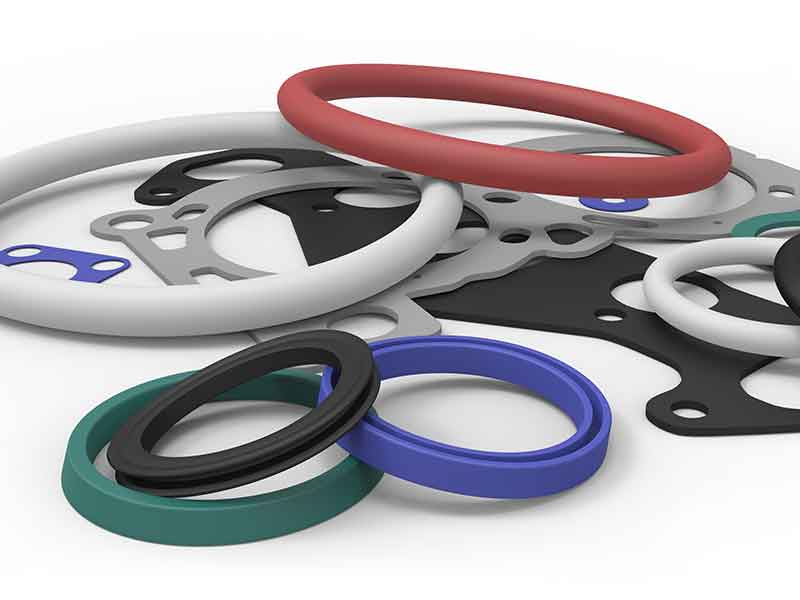

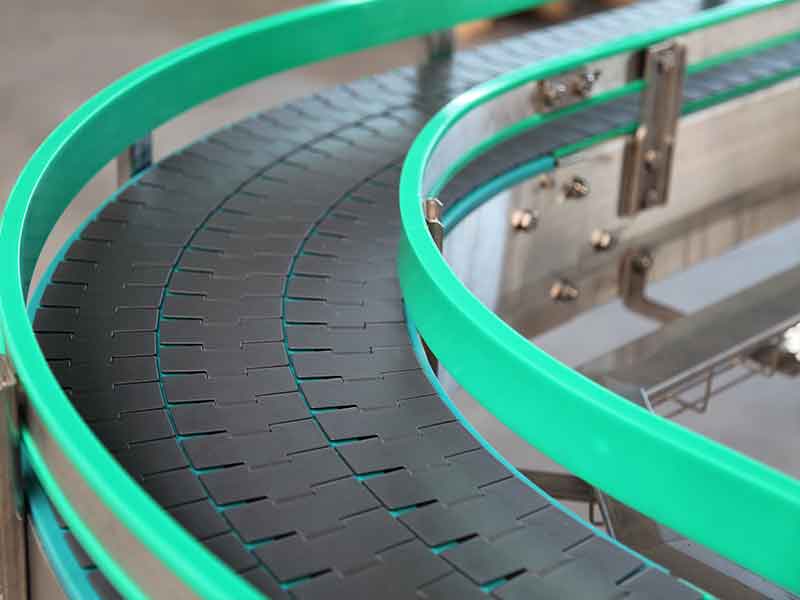

Typical applications

Due to the enormous range of property requirements, such as softness/hardness durometer values from low Shore A to high Shore D, application temperatures from -60°C to 150 °C, as well as excellent combinability with other plastics, TPE compounding can be very demanding. Powdered fillers, flame retardants and additives have to be worked in in the compounding process, as well as oils of various types plus liquid reagents or additives. The polymers utilized for TPEs often have widely varying or completely different melting temperatures and viscosities.

All of these challenges are well mastered by sophisticated process technology and BUSS compounding machinery for thermoplastic elastomers. Compared with other systems, the BUSS Kneader can make much better use of its strengths for these specialized compounds.

Compounding requirements

Thanks to its moderate and adjustable shear rates, melting energy dissipation is highly efficient so that there is no generation of hotspots as is common with other systems. In the mixing zones the enormous number of mixing cycles enables unsurpassed mixing efficiency no matter how high the additives content. If reactive modification is required, liquids are injected directly into the melt pool through hollow bored kneading pins. This takes place at the optimal positions virtually anywhere along the processing chamber of the compounding machinery. The liquid component is therefore mixed in immediately and very efficiently, thus preventing the liquids from coating metal surfaces and resulting in de-mixing or flashing off of these expensive liquids as can be seen with other compounding methods. Dynamic vulcanisation processes are also mastered with the BUSS Kneader technology.

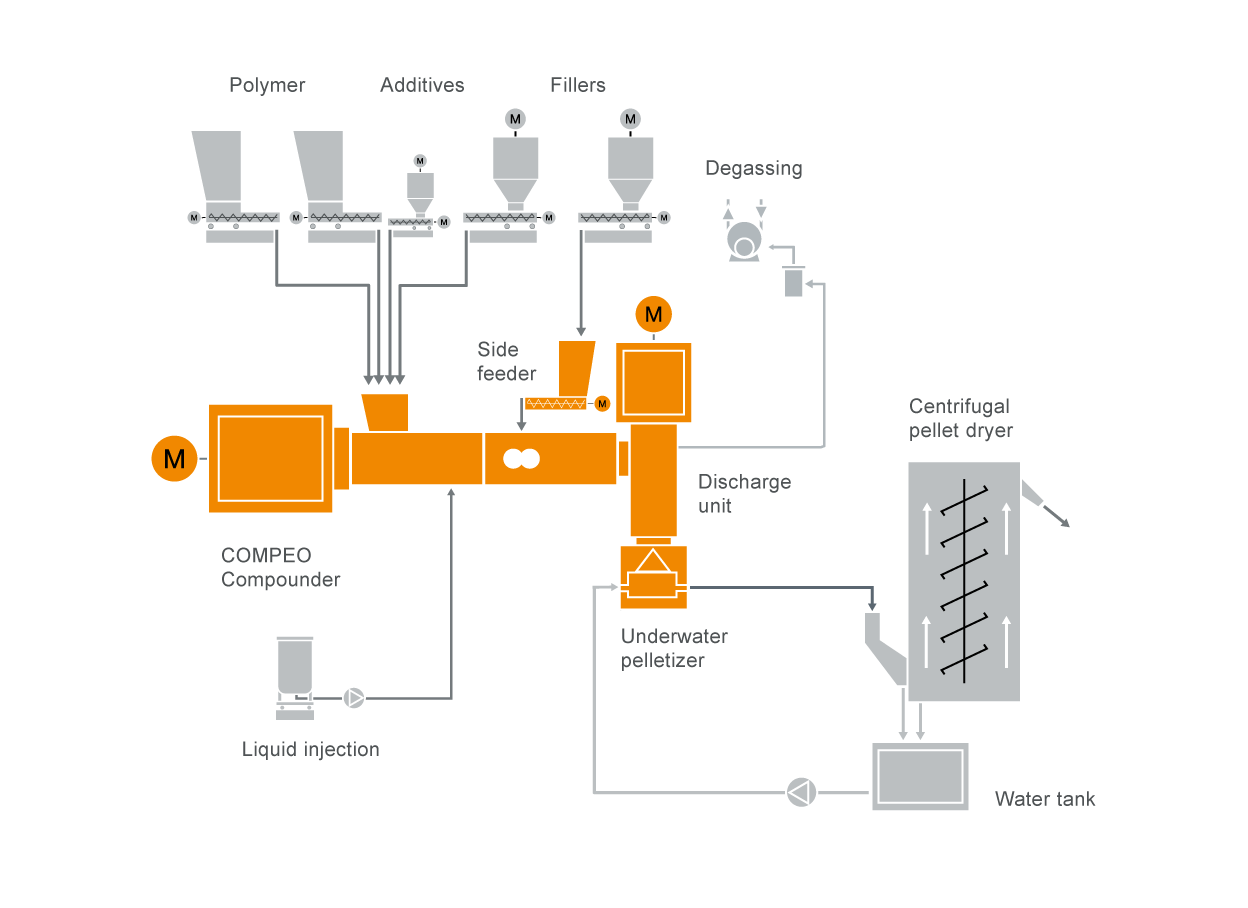

The BUSS Kneader’s two-stage system systematically separates the compounding from the pressure build-up stages so that each stage can be independently optimized. In the case of TPE compounds a flanged-on discharge extruder is normally used to build up pressure for pelletizing or further processing. The hinged housing of the BUSS Kneader and the retractable casing of the discharge extruder ensure fast and easy access to the process sections for high system availability.

Together with broadly based BUSS compounding process expertise, the modular design and therefore adaptable arrangement of the entire compounding line, make the BUSS Kneader first choice for compounding TPEs of all classes, as witnessed by the numerous plants already installed in this field.

Typical compounding plant layout for Thermoplastic Elastomers

BUSS compounding systems offer the following specific benefits

Learn More

Downloads

-

COMPEO

-

Laboratory Kneader MX 30